| This article or section may have been copied and pasted from another location.

Please review the source and remedy this by editing this article to remove any non-free copyrighted content and attributing free content correctly, or flagging the content for deletion. |

The Leader T2 MK5 Series weapons were chambered for the 5.56x45mm NATO cartridge and manufactured by Leader Dynamics of Smithfield, NSW Australia (1978-1982/1983). The Leader was the brainchild of weapons designer Charles St. George. It was originally a contender for a 5.56x45mm Australian military service rifle to replace the then-issued L1A1 rifles. What was unique about this endeavor was that Australia had never designed or manufactured its own commercial gas operated semi-automatic rifle. The rifle was abandoned when the Steyr AUG was adopted for use by the Australian military.

History[]

Charles St. George designed the production tooling and the factory at Smithfield began to initially turn out 200 units per month, which increased to 400 per month some months later. St. George developed a select-fire version called the T2 (including a carbine version of the T1 Leader) which attracted the interest of the Australian Defence Force, as well as foreign arms companies, including Luigi Franchi (a subsidiary of Beretta) in Italy, Fábrica Militar de Braço de Prata in Portugal, and foreign militaries, such as the Sultanate of Oman Armed Forces. ATA Target Systems of Albury NSW hosted the visitors, and Charles St. George together with Terry Dinnen demonstrated the Leader weapons on ATA's Dart System. The Leader demonstration resulted in Oman placing trial weapon orders for 12 Leader select-fire rifles (SAR) and 12 Leader assault carbines (SAC).

During this period, Charles St. George departed for Europe and conducted demonstrations in Portugal, Malta and Italy. Luigi Franchi were very impressed with the Leader and wanted to purchase a manufacturing license with customers in Europe and Asia. Unfortunately, Jack Allen and Brian Shaw, the two other partners in Leader, were not able to conclude a satisfactory contract with Luigi Franchi. Franchi eventually developed their own weapon.

The Leader was originally imported into the U.S. by Ed Hoffman and Tim Painter of World Public Safety, CA. The Leader was exhibited at the New Orleans Shot Show and orders in excess of $3,000,000 were written. The original buyers/distributors were John Giovino NY, Bumble Bee CA and Ellett Brothers. These weapons are quite rare in the US as very few (less than 2000 rifles) made it into the country.

In 1982 St. George split from both Brian Shaw and Jack Allan and moved on and established Armtech Pty Ltd.

Leader Dynamics was subsequently sold off to a businessman who formed his own company, Australian Automatic Arms, and started to make the Leader rifles in Tasmania. They differed in lacking the carrying handle of the Leader and coming with a 30-round magazine.

Design details[]

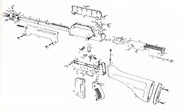

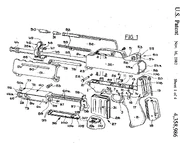

The charging handle, like that of the Heckler & Koch G3, ran from the forend to the bolt, was non-reciprocating, and could fold forward out of the way. It was mounted over the left action rod and supported by the barrel extension. The cylindrical flash hider was similar to that on the early model Colt Commando models (and suffered from the same problems). It had a diopter rear sight and a hooded post front sight.

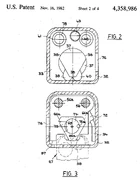

The weapon is quite simple and tooling cost was kept to a minimum. The receiver was a simple 16 gauge steel square tube readily available and saved thousands of dollars in die costs. Later variants use a triangular 60˚ rotating bolt to ease maintenance and production costs.

Charles St. George had to convince Australian engineering companies that it was possible to make firearm parts and that close tolerances were not imperative, as is the common belief. Barrels from Lithgow were too expensive so St. George designed and built his own button rifling machine using a self rotating button with a pushing motion. The barrel blanks were imported from Parker Hale in the United Kingdom with H&K providing the chamber machining details and Charterded Industries of Singapore supplied the 20 round M16 magazines.

The Leader actually had a self-cleaning gas system without the need for a gas regulator. The bolt carrier group was assembled into a modular system, obviating the loss of parts during dis-assembly. Simple spot welds were used throughout the fabrication and full use of early powder-metal parts that were used for the rear sight system and magazine latch.

The cylindrical flash hider was rated as either insufficient or ineffective and was usually replaced by an aftermarket Colt AR-15/M16 A2 "birdcage" model by owners. The loose tolerances for the magazine well could allow the magazine to move up inside it when the bolt was pulled to the rear, causing potential feeding malfunctions. The chamber was sometimes too tight on early models, causing failures to extract. Later models made by AAA were made to tighter tolerances and usually eliminated many of these problems.

Variants[]

SAR[]

The Semi-Auto Rifle (SAR) had a 16.25" barrel and synthetic stock.

SAC[]

The Semi-Auto Carbine (SAC) had a 10.5" (266 mm) barrel and synthetic stock.

SAP[]

The Semi-Auto Pistol (SAP) (dubbed the "Tasmanian Devil") was a pistol-gripped stockless version of the SAC. It came with a sling to brace it during firing. Only 700 were imported into the US before being banned in 1994.

SP[]

The Sporting Purpose (SP) had a long barrel and wood furniture and was sold as a sport shooting and hunting weapon.

Semi-automatic weapons were banned in Australia in 1996 following the Port Arthur massacre. The Leader was soon after withdrawn from production.

Of interest to those that study weapons, designs and evolution, Barret Firearms copied and uses the Leader Triangular breech bolt design for the M82A1 and its bolt action rifles.

Gallery[]

References[]

| |||||||||||